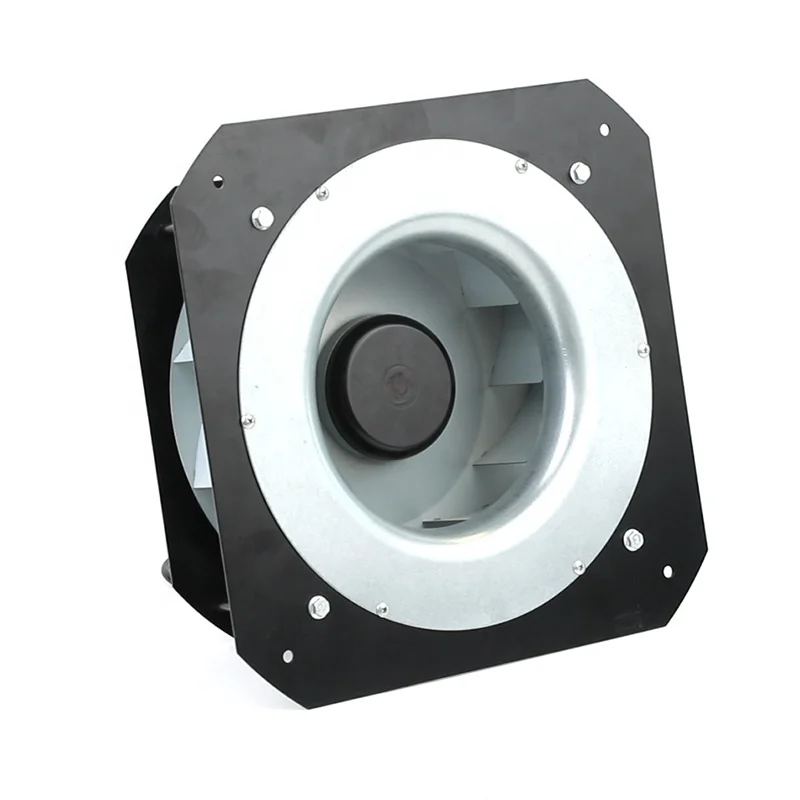

O správném průtoku vzduchu je v oblasti průmyslové výroby a zpracování klíčové. Zde přicházejí na řadu reverzní vyléčené centrifugální ventily. Tyto ventily dosahují vysoké výkonnosti, takže pohybují velkou dávkou vzduchu s minimálním poklesem statického tlaku. Používají se pro různé aplikace, jako je větrání, sušení, chlazení nebo topení.

Větráky se zpětně nakloněnými listy mají mnoho výhod, které ospravedlňují jejich použití. Jsou to větráky vyvinuté pro generování velkého objemu vzduchu při nízkém rozdílu tlaku, což je dělá levnějšími a energeticky účinnějšími pro průmyslové aplikace proudění vzduchu. Navíc jsou tyto větráky vhodné pro použití v aplikacích s vysokým statickým odporom díky svému elastickému tlaku.

Ventilátory se zpětně skloněnými stříkači běží nižší rychlostí otáček, což je důvodem jejich tichého fungování ve srovnání s jinými typy ventilátorů dostupných na trhu dnes. To je důvodem, proč jsou vynikající pro použití v prostředích, kde je třeba udržovat nízkou úroveň hluku, například v nemocnicích, knihovnách nebo školách.

Univerzální - Používány v široké škále aplikací. Mají široké uplatnění, obvykle se používají v systémech HVAC, tj. v jednotkách na ovládání vzduchu (AHU) a balených jednotkách na střeše, stejně jako v chladičích a průmyslových aplikacích atd. Rotorní ventily Masoneilan se také používají v průmyslových aplikacích, včetně sběru prachu, sušení a manipulace s materiály.

Ventilátory se zpětně nakloněnými vánky jsou navrženy podle pokročilých konceptů, které se používají v průmyslovém zařízení. Tyto ventilátory mají účinné zpětně zakřivené vánky a poskytují nepřetržitý proudový tok. V jednom provedení je ventilátor během ustáleného provozního stavu operován při konstantní rychlosti a takto pohání vzduch přes teplotní řídící senzor 34, aby udržoval požadovaný objem vzduchu při nízkém spotřebě energie.

Dalším typem centrifužního ventilátoru, který je často používán v průmyslových aplikacích, jsou ventilátory se zpětně nakloněnými vánky, které rovněž umožňují široké spektrum průtoků. To znamená, že mohou být použity pro aplikace vyžadující vysoké průtoky vzduchu, včetně manipulace s materiály, sběru prachu a systémů větrání.

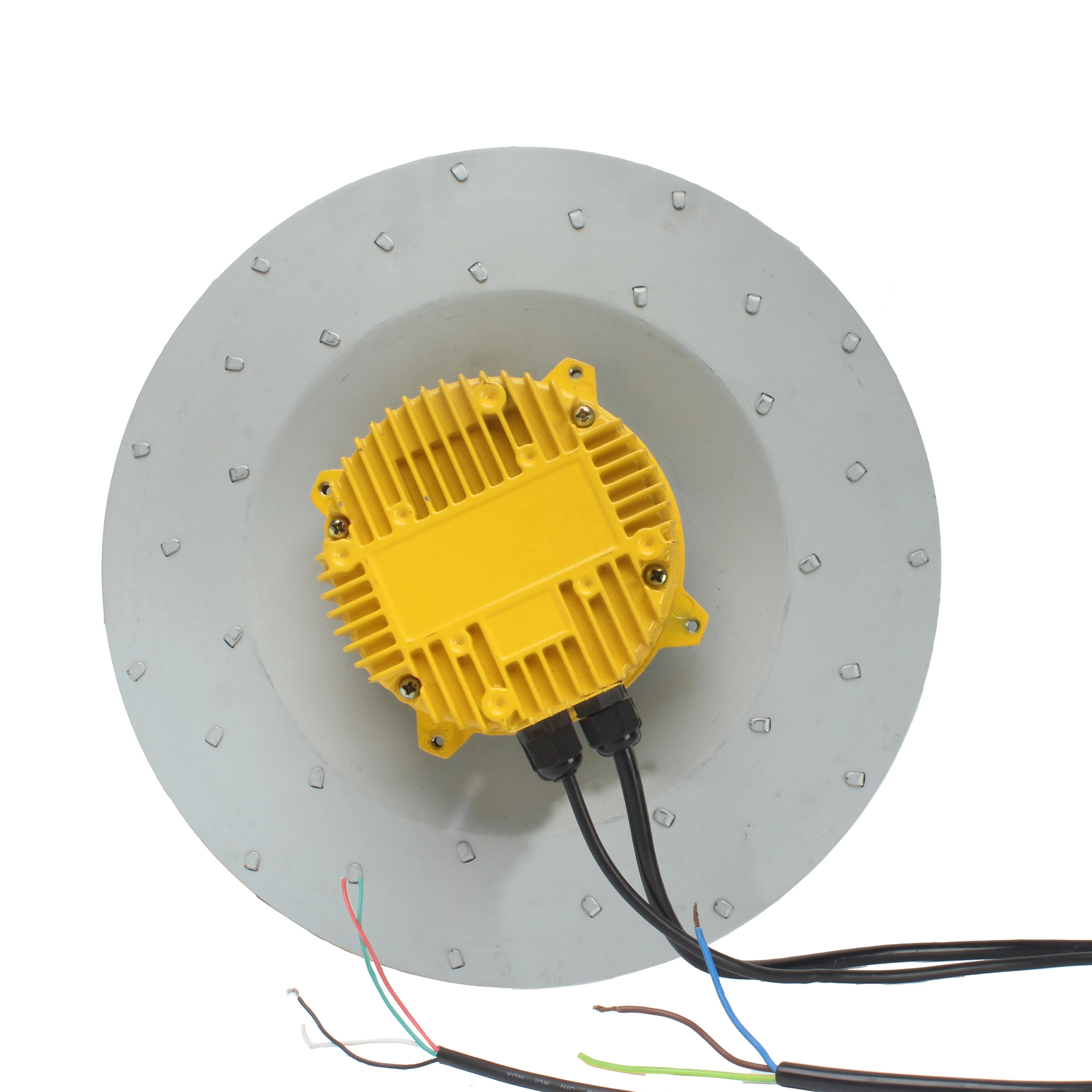

Navíc jsou lopatky natočené dozadu vyrobeny s speciálním návrhem lopatky známým jako úplně zakřivená dopravní kolo a zlepšuje účinnost v aplikacích s vysokým statickým tlakem. Ventilátor tohoto typu se nazývá SWSI, nebo jednoduchá šířka - jediný vstup a možnost návrhu lopatek natočených dozadu mu umožňuje dosáhnout maximální účinnosti v systémech, kde hraje důležitou roli odpor statického tlaku.

Centrifugální ventilátory s lopatkami natočenými dozadu jsou více uznávané než jiné obecné průmyslové aplikace větrání díky své vysoké účinnosti a ekonomickosti. Mají silové motory a jsou postaveny z některých z nejlepších materiálů, takže můžete být si jisti, že vaše teplý vzduch bude efektivně cirkulovat celou zimu. To znamená, že mají nízkou údržbu a celkově stojí majiteli méně.

Navíc dodávají vysoký průtok vzduchu při rozumně nízkém spadu tlaku, což snižuje celkovou spotřebu energie systému. To by je činilo dokonalými pro použití v aplikacích, které vyžadují energetickou účinnost. Použití větráků se zpětně nakloněnými středisky určitě sníží spotřebu elektřiny a poskytne viditelné výhody pro průmyslové podniky.

Větrák se zpětně nakloněnými středisky je řešením pro pohyb vzduchu ve středních až vysokých úrovních efektivity v průmyslu. Je to produkt vysoké kvality, který nabízí úžasný průtok vzduchu s minimálním spadem tlaku, velmi vhodný pro všechny druhy ventilačních požadavků, jako jsou aplikace na sušení/heating/cooling atd. Navíc jsou jejich šroubovice vyrobeny ve stylu zpětně zakřiveného, což slibuje optimální účinnost při aplikacích s vyšším statickým tlakem.

Pokud jste zvolili nainstalovat větrák se zpětně nakloněnými listy, pak trvanlivost tohoto zařízení může být méně častá v ohledu na údržbu a hluk. Tyto dveře na sběr prachu najdou široké uplatnění v systémech HVAC, procesech manipulace s materiály a používají se také pro výměníky tepla typu vzduch-vzduch.

Shrnutí: větráky se zpětně nakloněnými středivými listy nabízejí ekonomické a efektivní řešení průmyslového proudění vzduchu. Jsou nezbytné v moderních průmyslových procesech díky své univerzálnosti, efektivitě a spolehlivosti. Pokročilý design větráku se zpětně nakloněnými listy se používá ve mnoha odvětvích pro vysokokvalitní proudění vzduchu, energetickou účinnost a tím i nižší náklady na elektřinu.

zpětně nakloněný centrifugální ventilátor byl založen v roce 1996. Výrobní plocha podniku činí přibližně 3000 čtverečních metrů a je vybavena jedenácti dílnami. Jsme vedoucím výrobcem výzkumu a vývoje různých typů externích rotorových ventilátorů a také DC motorů. Máme více než 100 zaměstnanců, více než šest výrobních link a více než 25 let zkušeností s exportem.

jsou schopni přijímat objednávky na vzorky zadních šikmých větráků s centrifužními ventilátory, založené na návrhu, specifikacích a požadavcích na balení. A poskytují nejlepší servis po prodeji. Jak vždy, budeme dodržovat svůj závazek k hlavnímu konceptu podnikání: Ctižádost, Kvalita, Inovace a Vyhrávající spolupráce. Jsme oddáni návrhu strategie značky "Hangyan" pro provoz, tvoříme charakteristiky služeb s vynikajícím poměrem cena-výkon. Spolupracujeme se svými zákazníky s praktickým postojem a upřímnou spoluprací, abychom vybudovali lepší budoucnost.

Tým pro výzkum a vývoj má bohaté zkušenosti a vysokou kvalitu. Standardy kvality jsou velmi přísné. Používáme ISO9001:2015 jako standard našeho výrobního procesu a produkty také mají certifikace CE, UL, CCC a UL pro zadní šikmé centrifužní ventilátory.

jsme profesionální výrobci, můžeme nabízet motory a větráky různých typů za konkurenceschopné ceny. Větráky se zpětně nakloněnými listy zahrnují AC větráky, EC větráky, DC motory, nové produkty jsou ve vývoji. Naše společnost také spolupracuje s odborníky z univerzit pro vývoj inovativních větráků.

Naši profesionální pracovníci ve sběrovém týmu čekají na vaši konzultaci.