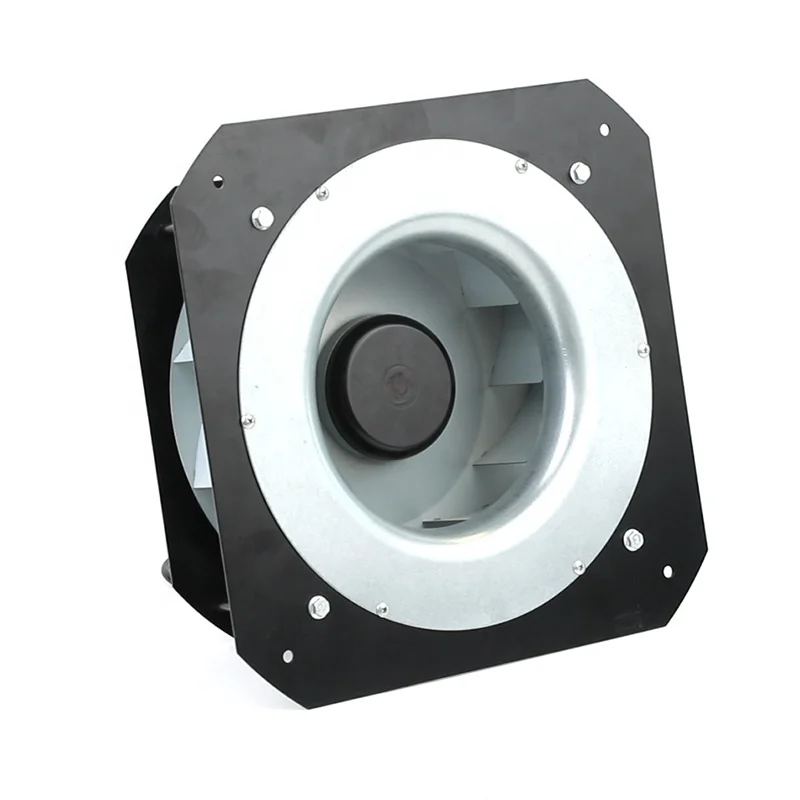

A radial centrifugal fan is a kind of machine that gets utilized in the transfer of air or gas. It has of a large wheel with revolving blades. The blades spin and they create suction so that it could suck in air/gas. The spinning wheel then evicts the air or gas through a fan.

Radial centrifugal blowers are very interesting devices that can improve the process of many applications by providing a large air flow or gas movement. The fan works on the principle of impeller (a wheel with blades), when this wheel rotate, it moves around and creates a low-pressure region which pulls in air/gas into its surrounding. Afterward, air or gas is pushed towards the fans housing using an impeller and it gets ejected through the fan outlet.

These fan work wonderfully at moving a ton of air in relative silence and use energy efficiently to boot. Some fans are even able to withstand particular gases without incurring any damage.

Truly, the radial centrifugal fans have outdone themselves in giving you. They are widely used because they can move large volumes of air or gas, and do so without producing excessive noise while efficiently consuming energy. Moreover, some models are even made to handle corrosive gases such as hydrogen chloride and ammonia without getting damaged.

Choose a fan based on the volume of air or gas to be handled and pressure requirements. Another point to think about is what type of gas or air it will work with and how well the motor as well as drive system function.

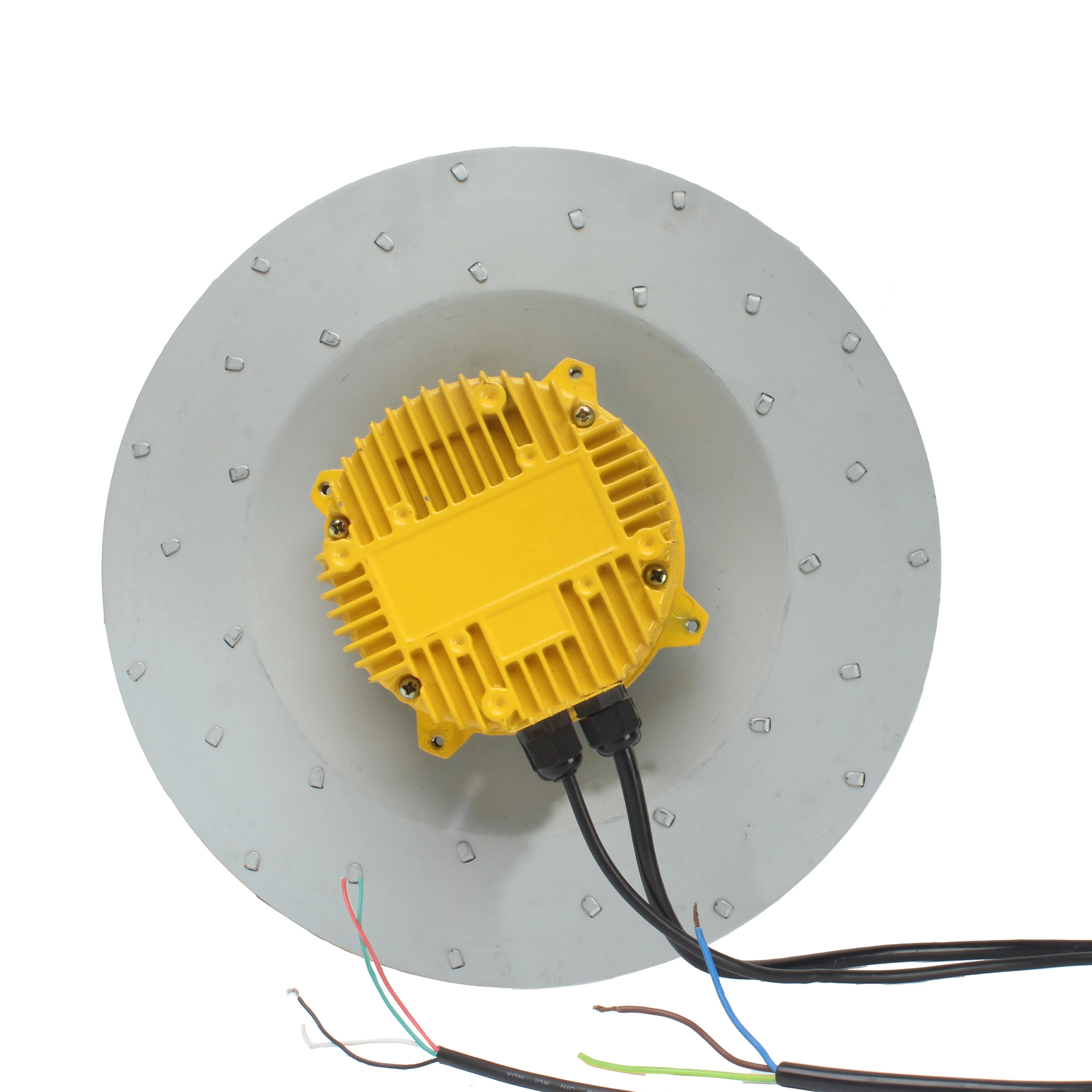

Many factors are needed to be taken into account while choosing the right radial centrifugal fan. A capacity that needs to be calculated in term of the volume of air or gas being moved will determine both fan housing, and blower wheel size. Also critical to fan selection are the required pressure output of the fan and either gas or air properties in question. Also, sizing the motor appropriately to be able to drive up fan impeller at the required speed and also making sure that the drive system is robust enough for long term operation are key considerations.

To prevent this, it is in your best interest to clean the fan on a routine basis and keep an eye open for any malfunctioning parts. The motor and drive system should be clean & well operating.

Most importantly, you have to put some efforts in ensuring that your centrifugal fan continues offering optimum performance throughout its life as long as it is still useful and efficient. Basic maintenance includes inspecting and rinsing the fan blades as well as their housing area for any dirt or debris. In conclusion, regular checks on bearing operation and proper greasing as well as timely replacement of the bearings are two fundamental steps in keeping your fan running smoothly. Also, ensuring the cleanliness and functionality of the fan drive system such as drive belt or coupling is essential to keep it running smoothly in longer terms.

NFL fans keep getting smarter. And they are also working on other designs to improve the lifespan and performance of fans. Smart motors McIver noted that some of the fans already do have smart sensors and motors to pick up alarms at an early stage.

The world of radial centrifugal fans is in a state of constant evolution for their performance, energy efficiency and longevity improvements. They also incorporate various advanced materials and coatings to increase corrosion resistance, as well optimize air handling capacity. Plus, modern models can control the speed and monitor your fans thanks to digitally controlled motors. One of the other key advancements here is in terms of sensors which can be programmed to forewarn about faster wearing-out and performance-related problems affecting fans.

To sum it all up, radial centrifugal fans are essential machines to keep industries going. Learn how they work, take good care of them and if you play your cards right, you can keep the same fan for years without problems.

a professional manufacturer are in a great position to provide the majority fans and motors affordable prices, and prompt delivery. Our products include AC fans, EC fans, DC motors. New products are under development. We also work with many university radial centrifugal fanexperts to handle new fans.

have a highly-qualified R D department with extensive experience. quality radial centrifugal fanare strict. We are ISO9001:2015 certified production Our products also have CE and UL certifications. CCC and the UL certification.

company was founded in year 1996. area of the production plant of business is approximately 30,000 square meters, equipped with eleven radial centrifugal fan.We are top manufacturer researching and developing various types of externalrotor motors and DC motors.We have over 100 employees , more than 6 production lines and over 25year of experience exporting.

will accept orders on basis of customer designs, with customer specifying the design, specifications packaging requirements. we provide best after sale service. As always, we'll remain true to our core business idea: Integrity, Quality, Innovation and Win-Win". We keep with the time to create "Hangyan" brand operation strategy,and create service features that are excellent and cost-effective.We collaborate with our customers through the same radial centrifugal fanand honesty collaboration to build a better future.

Our professional sales team are waiting for your consultation.